|

|

|

|

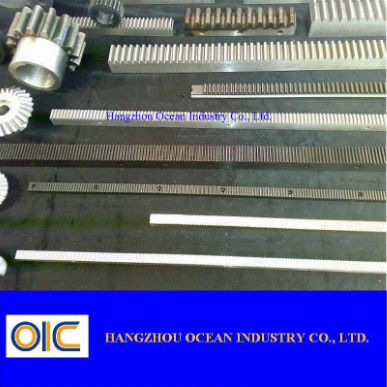

30000 Units Gear Racks Module 1.0 Designed for Sliding Gate Motor Systems Offering and Gear Engagement in Automation Machinery

| Τύπος: | Τύποι | Ικανότητα: | 30000 μονάδες |

|---|---|---|---|

| πλάτος: | 20 mm | Μονάδα μέτρησης: | 1.0 |

| Χρήση: | Γλιστρώντας μηχανή πυλών | χρώμα: | Φύση |

| Εφαρμογή: | Βιομηχανικά μηχανήματα | Προφίλ δοντιών: | Ευθεία |

Product Description:

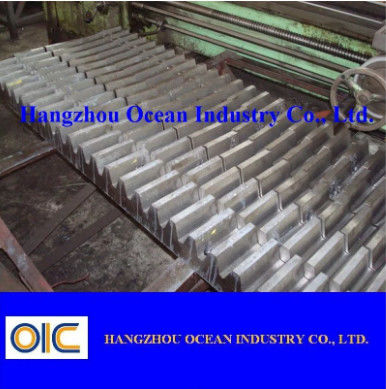

Gear racks are essential components widely used in various mechanical systems, providing precise linear motion and power transmission. Our range of gear racks is designed to meet the demanding needs of different equipment, ensuring reliability and high performance. These gear racks come in various kinds, allowing you to select the perfect match for your specific application, whether it is for industrial machinery, automation equipment, or heavy-duty mechanical systems.

The gear racks are manufactured with a natural color finish, which not only enhances their aesthetic appeal but also indicates the use of high-quality raw materials that ensure durability and resistance to wear. This natural color finish is a testament to the product’s robust construction and its ability to maintain performance under challenging working conditions.

One of the standout features of our gear racks is their impressive capacity, with an ability to handle up to 30,000 units. This high capacity makes them suitable for heavy-duty rack applications where strength and endurance are critical. Whether you are dealing with large-scale industrial equipment or specialized machinery, these gear racks provide the strength and reliability needed to keep your operations running smoothly.

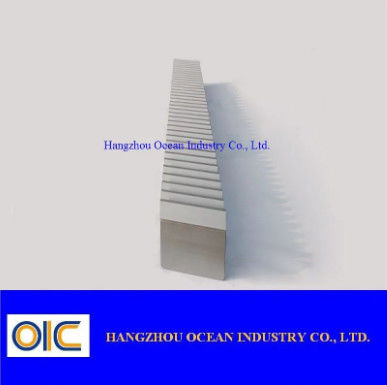

Our gear racks are designed with a module of 1M, which is a standard measurement in gear manufacturing. This modular design facilitates easy integration with other gear spare parts and components, ensuring compatibility and simplifying maintenance or replacement tasks. The 1M module also ensures smooth engagement with pinions, reducing wear and extending the service life of the gear system.

Featuring a straight tooth profile, these gear racks offer several advantages that make them ideal for a range of mechanical applications. The straight teeth ensure efficient power transmission with minimal backlash, providing precise linear motion control. This tooth profile is particularly beneficial in heavy-duty rack settings where accuracy and strength are paramount. Additionally, the straight tooth design simplifies manufacturing and maintenance processes, making these gear racks a cost-effective solution for your equipment needs.

Our gear racks are not just components; they are critical gear spare parts that contribute significantly to the overall performance and reliability of your machinery. By choosing our gear racks, you are investing in equipment that has been engineered for longevity and consistent performance under heavy loads. These heavy-duty racks are extensively tested to meet rigorous industry standards, ensuring they can withstand the stresses of demanding environments without compromising functionality.

In summary, our gear racks offer a combination of versatility, durability, and precision. Available in various kinds to suit different applications, finished in a natural color that reflects their high-quality build, and boasting an ability to handle up to 30,000 units, these gear racks are the ideal choice for heavy-duty rack requirements. With a 1M module and a straight tooth profile, they provide reliable and efficient power transmission, making them indispensable gear spare parts for any equipment that relies on linear motion and gear-driven mechanisms.

Whether you are upgrading existing machinery or designing new equipment, our gear racks deliver the performance and dependability you need. Trust in our products to provide the strength and precision necessary for your heavy-duty applications, ensuring smooth operation and long-term success in your mechanical systems.

Features:

- Product Name: Gear Racks

- Processing Method: Hobbing for precise gear cutting

- Tooth Profile: Straight teeth for smooth operation

- Condition: New and unused gear spare parts

- Color: Natural finish

- Surface Treatment: Black Oxide for enhanced durability

- Ideal for use as Gear Spare Parts and Gear Mold components

Technical Parameters:

| Shape | Rack Gear |

| Length | 1000mm |

| Ability | 30000 Units |

| Application | Industrial Machinery |

| Type | Kinds OF |

| Surface Treatment | Black Oxide |

| Width | 20mm |

| Tooth Profile | Straight |

| Usage | Sliding Gate Motor |

| Color | Nature |

Applications:

The MW M4 Gear Racks, proudly manufactured in China, represent a pinnacle of precision and durability in the field of mechanical components. These gear racks are designed with a module of 1.0 and a length of 1000mm, ensuring a perfect fit for a wide range of industrial applications. With an accuracy rating of DIN 6, these racks guarantee high precision and smooth operation, which is critical for maintaining the efficiency and reliability of mechanical systems.

One of the standout features of the MW M4 Gear Racks is their surface treatment with black oxide, which provides excellent corrosion resistance and enhances the overall durability of the rack. This makes them highly suitable for heavy-duty applications where resistance to wear and environmental factors is essential. The black oxide finish also contributes to reduced friction and smoother meshing with gears, thereby extending the lifespan of the entire gear assembly.

These Heavy Duty Racks are ideal for use in demanding industrial environments, including manufacturing machinery, automation systems, and material handling equipment. Their robust construction ensures they can withstand substantial loads and harsh operating conditions, making them a reliable choice for industries such as automotive, aerospace, and heavy machinery manufacturing.

The MW M4 model is also available as Helical Gear Racks, which are especially beneficial in applications requiring quieter and more efficient power transmission. The helical design reduces noise and vibration, making these racks perfect for precision machinery and high-speed operations. Additionally, the helical gear racks complement Euro Racks standards, providing compatibility and ease of integration with European machinery and systems.

In summary, the MW M4 Gear Racks combine high accuracy, durability, and versatility, making them suitable for a variety of application occasions and scenarios. Whether it’s in heavy-duty industrial machines, precision automation systems, or Euro-compatible equipment setups, these gear racks deliver reliable performance and long service life. Their new condition and meticulous manufacturing standards ensure that users receive a product that meets stringent quality requirements and operational demands.

Customization:

MW presents the M4 model Gear Racks, expertly crafted in CHINA with a production capacity of 30,000 units. These Rack Gears feature a Mod of 1M and adhere to DIN 6 accuracy standards, ensuring precise and reliable performance. The surface is treated with a durable Black Oxide finish for enhanced protection and longevity. Our Gear Mold technology guarantees high-quality manufacturing, making these Gear Racks ideal for various applications including Fishing Gear Parts. Trust MW for superior Fishing Gear Parts that meet rigorous quality and performance requirements.

Support and Services:

Our Gear Racks are designed to provide reliable and precise linear motion solutions for a variety of industrial applications. To ensure optimal performance and longevity of your gear racks, please follow the installation and maintenance guidelines provided in the product manual.

For installation, ensure that the gear rack is mounted securely on a flat and stable surface, aligned properly with the pinion gear to prevent uneven wear. Use appropriate fasteners and torque settings as recommended.

Regular maintenance includes cleaning the gear racks to remove debris and applying suitable lubrication to reduce friction and wear. Inspect the gear racks periodically for signs of damage or excessive wear and replace components as necessary.

If you encounter any issues with your gear racks, such as unusual noise, vibration, or misalignment, consult the troubleshooting section of the manual. For technical assistance, professional support services are available to help diagnose and resolve complex problems.

We are committed to providing high-quality technical support and services to ensure your Gear Racks operate efficiently and effectively throughout their service life.

Packing and Shipping:

Each Gear Rack is carefully packaged to ensure it arrives in perfect condition. The product is wrapped in protective material to prevent scratches and damage during transit. It is then placed in a sturdy cardboard box designed to withstand shipping pressures.

For shipping, we use reliable carriers and provide tracking information so you can monitor your order every step of the way. We also offer secure packaging options for international shipments to guarantee safe delivery worldwide.

Our packaging and shipping process is designed to deliver your Gear Racks promptly and safely, ensuring your complete satisfaction with every purchase.

FAQ:

Q1: What brand manufactures the Gear Racks model M4?

A1: The Gear Racks model M4 is manufactured by the brand MW.

Q2: Where are the MW Gear Racks model M4 produced?

A2: The MW Gear Racks model M4 are produced in China.

Q3: What materials are used in the construction of the MW Gear Racks M4?

A3: The MW Gear Racks model M4 are typically made from high-quality steel to ensure durability and performance.

Q4: What applications are suitable for the MW Gear Racks model M4?

A4: The MW Gear Racks M4 is suitable for various industrial applications including automation equipment, robotics, and machinery requiring precise linear motion.

Q5: How do I determine the correct size of Gear Rack M4 for my project?

A5: To choose the correct size of the MW Gear Rack M4, consider factors such as the required pitch, length, module, and the gear pinion specifications. You can contact MW support for detailed assistance.

Υπεύθυνος Επικοινωνίας: Mrs. Lily Mao

Τηλ.:: 008613588811830

Φαξ: 86-571-88844378

-

M4 γαλβανισμένα ράφια εργαλείων συρόμενων πορτών 12X30

-

Ράφια εργαλείων μηχανών χάραξης λέιζερ μετάλλων 19X19

-

Οι μηχανές χάραξης λέιζερ κεντρίζουν κατ' ευθείαν CNC χάλυβα τα ράφια εργαλείων

-

Παράθυρο γύρω από το ελικοειδή ράφι εργαλείων χάλυβα και το γρανάζι

-

CNC DP12 αργιλίου εργαλεία γραναζιών

-

Νάυλον να τοποθετήσει συρόμενων πορτών ράφι εργαλείων βιδών πλαστικό